Bio-Design Case Study: Healthy Bandaids | Life Healing

Pratt Institute: Sustainable Design Certification

THE CHALLENGE

Innovate & marry two global industries:

The Band-Aid Manufacturing industry & The Leather Manufacturing Industry.

This Case Study develops a means to add ‘life’ to re-directed waste and creates a new product that is a healthier option.

This Case Study’s Design Objective was:

Stop the systemic global waste issue created by leather + band-aid manufacturing And:

Create a bio-designed product that marries leather’s waste to band-aids’ own waste issues.

Project Details

Role

Sustainability Researcher

Product Designer

Packaging Designer

Product Developer

Factory + Material Sourcing

What is Leather & How is it made?

Leather is chemically treated animal skin.

The skin is processed in three steps: 1 - preparation, 2 - tanning, & 3- crusting (finishing is an optional fourth step).

Step 1 - Preparation: The hide is being prepared for tanning by soaking it, removing the hairs and some of the proteins that are not essential for the final product.

Step 2 - Tanning: Tanning stabilizes the collagen and keratin proteins in the skin, makes leather flexible, and prevents it from drying out. During this process, the hide is immersed in a tanning liquid that slowly seeps through the whole thickness of the leather.

Step 3 - Crusting: In the final phase, the material gets thinned, colored, dried & softened with chemical & mechanical methods. This is where the Chromium Chemicals are added into the leather and the result includes Toxic Chemicals into the raw leather materials.

What is Chrome Tanned Leather Production?

Chrome tanned leather accounts for an astonishing 90% of leather in the world. Chrome tanning was developed during the industrial revolution as a faster, cheaper alternative to vegetable tanning. Chrome tanning is a global environmental disaster and puts the health of millions of leatherworkers and ordinary citizens at risk. The chrome tanned leather industry has pushed the environmental degradation and human health risks of chrome tanning out of sight and out of the minds of its consumers. Developing countries such as Bangladesh, India, and China, with lax environmental regulations and safety protocols for workers, account for the majority of the chrome tanneries.

Impact of Chrome Tanning Waste:

Solid waste from tanneries is commonly used for animal feed & fertilizer.

The reuse of this solid waste does nothing to remove the contaminants, it simply moves the chemicals directly into the chicken, fish, and farmland that are fed the toxic food.

Chickens that are fed tannery waste tested in Bangladesh had levels of chromium between 40% and 1700% higher

then the maximum recommended daily exposure according to the European Food Safety Authority.

You don’t need to be a trained scientist to grasp the implications of using tannery waste as animal feed and fertilizer.

These dangerous contaminants quickly come full circle back to human consumption.

Once in the food chain and water supply, tannery waste “can incite respiratory problems, infections, infertility, and birth defects.”

By reusing solid tannery waste, hazardous toxins are passed from animals and land, to humans, and through humans to their offspring.

The lasting impacts of these practices therefore become generational

Realistically speaking, if these chemicals have infiltrated farmland and the water table, the effects could be permanent, or at least significantly longer than a few generations.

While authorities have tried to crack down on practices of using tannery waste in food supply and fertilizer, the industry remains largely in the shadows.

What are Leather Remnants?

Leather remnants are the off-cuts, trimmings and left over hides that are not intended for use after their original purpose;

Both from the Tannery (where the leather is made) & Factory (where the leather is processed into a finished product).

What is the volume of Leather Remnants annually world-wide?

Infinite amounts: Produced by Tanneries and Production facilities

How are they currently being used or disposed of?

Currently they are being used to create Bicast Leather, which is a composit of lesser quality leather, or it is being sold in lbs to

individuals, sold to programs such as prisons or even schools for activities, OR they are being thrown away into the landfills.

How else are we able to Re-Purpose these Leather Remnants?

What if we could extract the embedded Collagen out of the remnants and then use this extracted collagen to create new products?

It is at this junction is where this Case-Study’s focus begins:

Specifically extracting collagen out of remnant or waste leather and creating a ‘healthy’ bandaid from this material.

How to Extract Collagen from Leather?

Brazilian Chemist, Joana D’Arc Felix de Souza created and owns the global patent named:

“Extraction process of hydrolyzed collagen and of chrome/collagen complex from chrome tanned leather residues”

Brazilian Chemist, Joana D’Arc Felix de Souza created and owns

the global patent that allows for collagen to be extracted from Chrome Tanned Leather.

Raised by a tanner and a maid, she now advocates for underprivileged youth.

Joana D'Arc Félix de Sousa ( October 22 , 1963 in Franca ) is a Brazilian professor and scientist . She received the Kurt Politzer Technology Award in the "Researcher of the Year" category in 2014.

How are Band-Aids Made?

Most band-aids are made of plastic. The adhesive sheet of a band-aid is usually made from either PVC, polyethylene, or polyurethane.

It is a single-use plastic item, but unlike other single-use plastics, band-aids cannot be replaced by a reusable item. Polyurethane is, like all plastics, petroleum-based and is the same toxic compound found in chemical-laden mattresses. While polyethylene is considered a “safe plastic,” the process of manufacturing it requires industrial chemicals including butane, benzene, and vinyl acetate, making the process less than eco-friendly. PVC, or polyvinyl chloride or vinyl, it’s the most toxic plastic for both our personal health and environment.

Vinyl releases many dangerous chemicals, including dioxins, phthalates, lead, and more.

Band-aids are not sustainably-made, they are not biodegradable and they are bad for our health.

And while we aim to throw them all in the bin, sometimes they fall off and end up in the environment & landfills.

How many bandages are thrown away each year?

Estimated at 2 billion adhesive bandages are sold each year, meaning that 4 billion release liners are thrown away from bandages alone!

New Developments in ‘Wound Healing’ & Band-Aid Industry

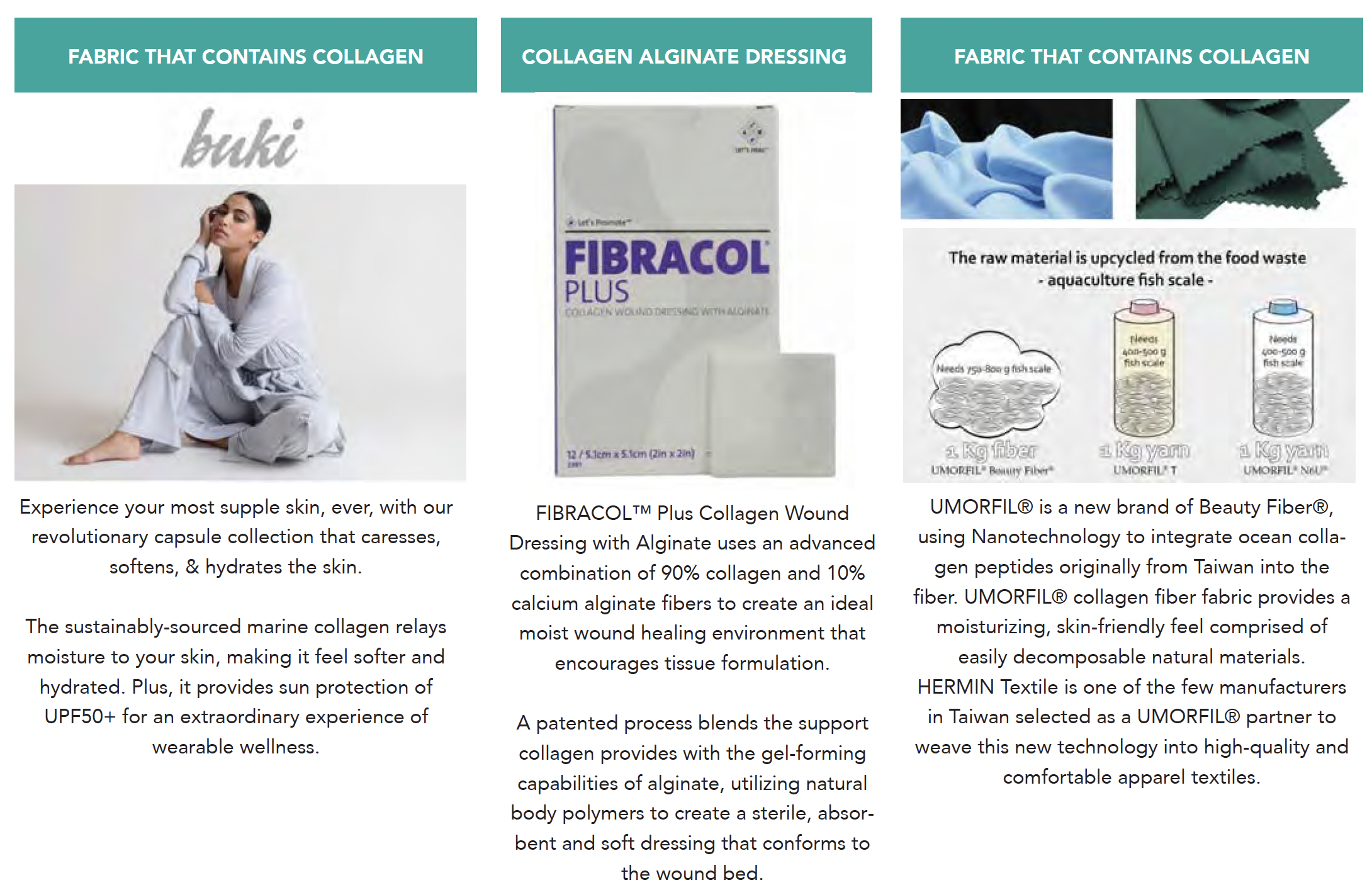

Examples of Collagen being combined with other materials:

Collagen + Life = ‘Life Healing WoundCare.’

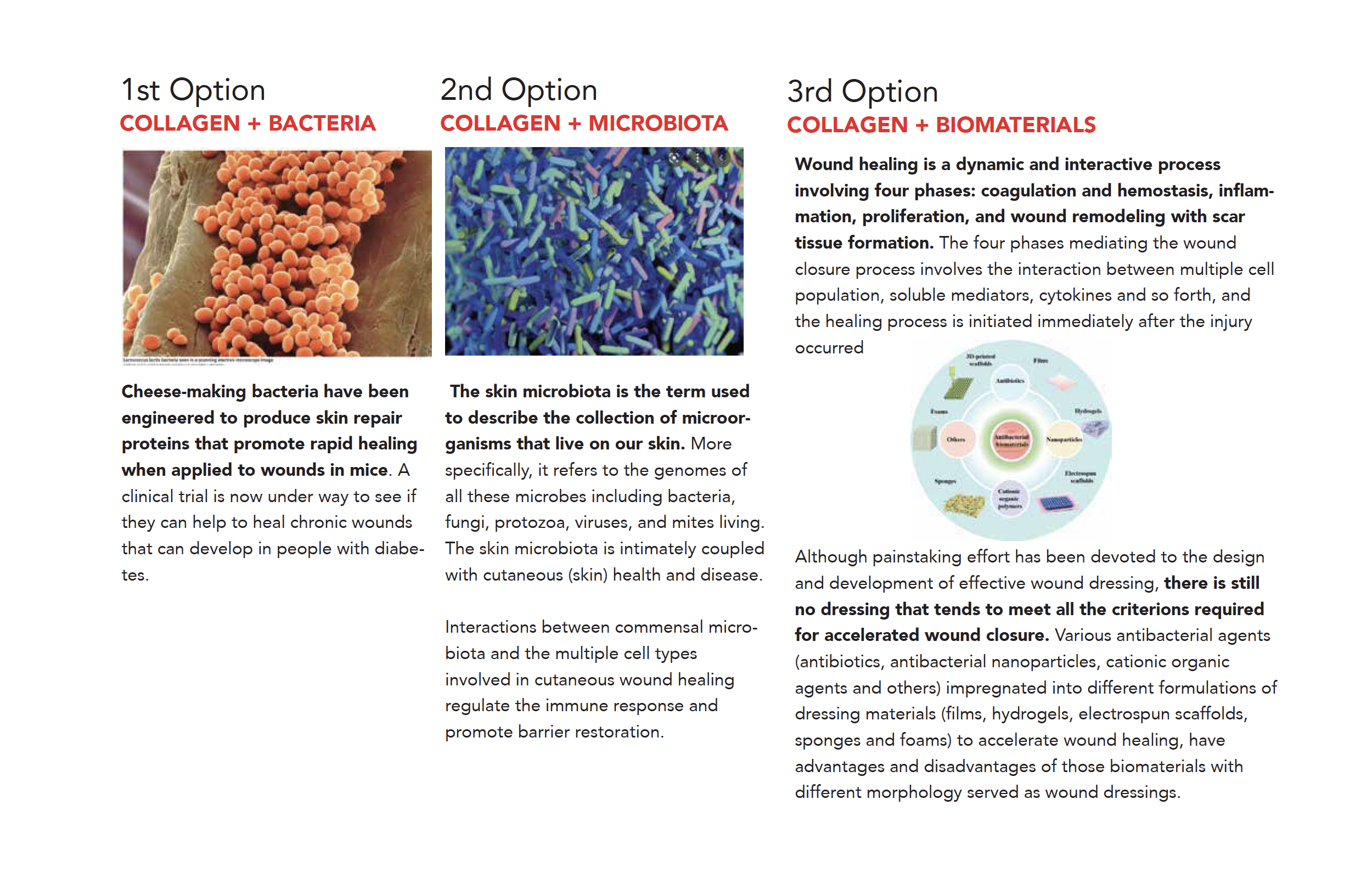

Options for Bio-Designed wound care using Extracted Collagen + Microbes: Named as: ‘ECM’

Formalizing Design Concept:

Phase 1: Location of Use, Application + Packaging

The intention for this new ECM or ‘Extracted Collagen + Microbes’ Wound Care Bio-Designed Product, is to phase out this concept into a few stages of production and use.

The 1st Phase would be strictly to Medical Facilities, where human, or non-human tissue would be able to have it applied by a professional.

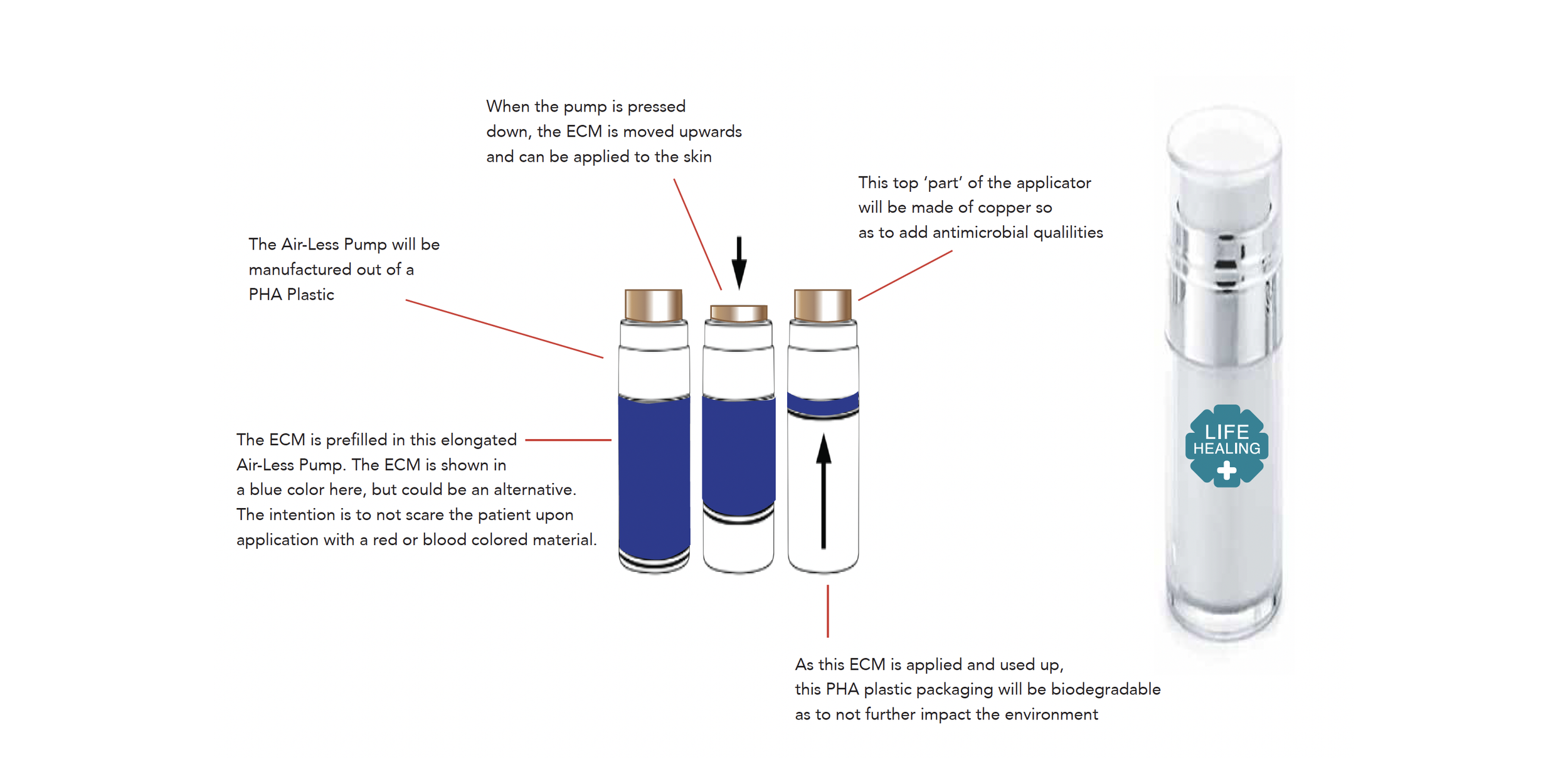

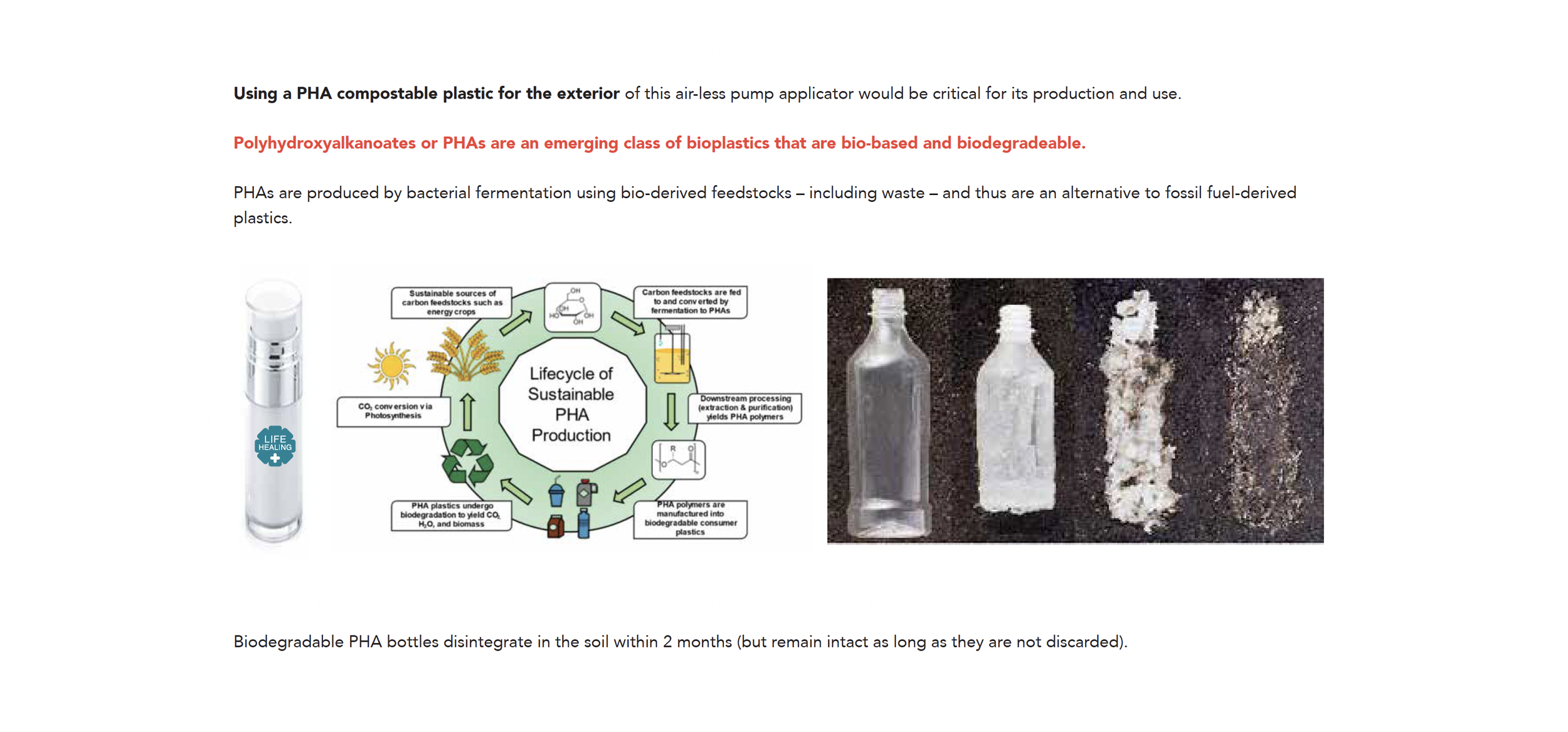

Using a PHA compostable plastic for the exterior of this air-less pump applicator would be critical for its production and use.

Additionally the air-less pump’s top part, where the ‘Extracted Collagen + Microbe’ would be administered out of, would made of a copper metal,

as this material has intrinsict antimicrobial qualities.

This 1st phase packaging is not-refillable, but is biodegradable and intended for a one 1 patient use.

As the exposure to ‘bad’ bacteria that could infect the patient is a risk that was not something for consideration in this 1st Phase.

Perhaps as this design is in its Phase 1 use, and developed further the refillable nature of the extracted collagen within the pump could be an option.

Options for Bio-Designed wound care using Extracted Collagen + Microbes: Named as: ‘ECM’

Packaging Design Details:

Life Healing Bio-Bandaid